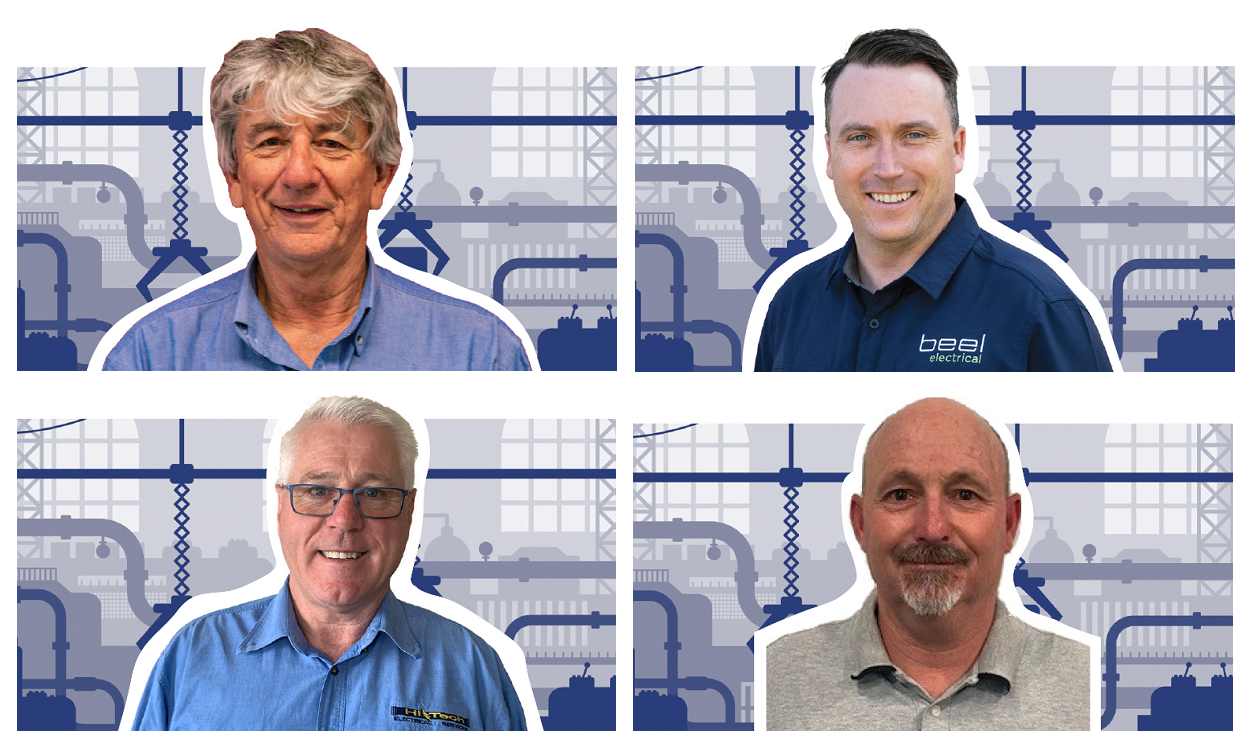

Insights from Industry Thought Leaders

ShareOur panel of Industrial experts enlighten us on all things Automation and Smart Technologies.

In the fast-evolving electrical industry, staying ahead is crucial. Our panel of experts with 150 years of combined experience explore the future of industrial projects, offering insights on automation, smart technologies and emerging innovations. Their insights highlight key challenges, opportunities and actionable strategies for businesses to adapt to and use to succeed.

|

Trevor Quaini

|

What types of work do you and your team specialise in?

I lead the Middy's Industrial team which specialises in a wide range of industrial electrical solutions, including motor control, automation, low-voltage systems and custom switchboard designs. We provide expert support for variable speed drives and motor starting applications. Our team delivers end-to-end solutions, from product supply to technical advice and project support.

How do you stay ahead of the latest trends, technologies and regulations in the industrial sector?

Staying ahead in this field means constantly learning and adapting. The pace of change is incredible. Automation is advancing and the number of companies evolving to meet these new needs is growing. We keep up with the latest trends by working closely with technology providers like Siemens and Schneider Electric, who are at the forefront of innovation. Attending industry conferences, investing in staff training and partnering with experts is essential to stay competitive.

What changes do you see in industrial electrical work in the next 5-10 years, especially with automation and smart technologies?

The next decade will be transformative. Automation will continue to replace traditional jobs, and smart technologies will become even more integrated into production lines. We’re already seeing jobs shift from manual labour to technical roles where workers monitor and maintain automated systems. As the demand for more efficient and reliable systems grows, the need for specialised technicians will increase. It’s not about fewer jobs, but different types of jobs that require a deeper understanding of automation.

What’s your vision for the future of industrial electrical work, and how are you or your team preparing for it today?

The future is all about efficiency and reliability. Companies want systems that reduce downtime and increase output, and automation delivers that. To prepare, we’re investing in training to ensure our team is skilled in operating and troubleshooting these advanced systems. We’re also partnering with key players in the automation industry to ensure we’re always on top of the latest technology. It’s about being ready for whatever the future brings and having the knowledge to implement and manage cutting-edge systems.

In your experience, which innovations have had the most significant impact on industrial electrical systems?

The biggest impact has been the integration of fully automated systems and the ability to monitor them remotely. For example, the automation solution we worked on for Patrick’s dockyard with Siemens is fully monitored off-site, reducing the need for on-site staff while maintaining operational efficiency. These innovations allow companies to achieve higher output with fewer resources, which is a huge leap forward for the industry.

Is there a specific project or achievement in the industrial space that you are particularly proud of?

I'm particularly proud of my team's diverse backgrounds in the industrial sector, which enables us to cover all bases and provide comprehensive support and solutions to our customers. This diversity allows us to approach challenges from multiple angles, ensuring we meet our clients' unique needs effectively. We're also actively building relationships with industry partners at the forefront of innovation, which enhances our capabilities. Additionally, taking our industrial customers on contractor trips has been a rewarding experience, allowing us to deepen those relationships and share valuable insights into the latest trends and technologies in the field.

|

Benjamin Beel

|

What types of work do you and your team specialise in?

Our expertise primarily lies in service and maintenance, with a strong focus on project work. Based on the Mornington Peninsula, Beel Electrical provides specialised support for wineries and distilleries, particularly concerning their equipment needs during harvest and production. Additionally, we offer regular servicing and shutdown management for a plastic manufacturing company, alongside project work such as installing new production lines.

How do you stay ahead of the latest trends, technologies and regulations in the industrial sector?

We actively keep up with industry advancements by regularly attending professional development courses, trade shows and seminars. These events help us stay informed about emerging technologies, best practices and regulatory changes. Our strong relationship with Dean Sullivan from Middy’s Industrial team serves as a significant resource, allowing us to leverage his expertise to stay at the cutting edge of industry trends.

What changes do you see in industrial electrical work in the next 5-10 years, especially with automation and smart technologies?

We anticipate significant growth in automation and smart technologies within the industrial electrical sector. We're already seeing increased demand for advanced machinery like robotic arms, 5-axis trimmers and 3D scanning tools, which are essential for improving precision and efficiency. As this technology evolves, we expect a shift toward more integrated systems where machines can communicate seamlessly, driven by data input directly from advanced scanning tools into source code. This transformation will require specialised expertise in programming, system maintenance and troubleshooting, making adaptability and continuous learning key to staying competitive in the field.

What’s your vision for the future of industrial electrical work, and how are you or your team preparing for it today?

Our vision is one where automation, artificial intelligence and smart technologies play a central role in driving efficiency, safety and innovation. We foresee a future where electrical systems are increasingly integrated, with machines communicating autonomously to optimise production processes and minimise downtime. To prepare for this, our team is investing heavily in upskilling and training on the latest technologies, such as robotics, advanced control systems and data-driven automation tools. We're also fostering strategic partnerships, like our collaboration with Middy’s Industrial team, to ensure we're at the forefront of emerging trends. By staying agile and forward-thinking, we're positioning ourselves to lead in this rapidly evolving field.

In your experience, which innovations have had the most significant impact on industrial electrical systems?

One project that stands out is our custom design and installation of an Allen Bradley floor laser scanner on a robotic arm trimming machine. This setup was entirely tailored to meet the unique needs of our client, marking a significant achievement for our team. The project required close collaboration with Stefan Stainwall from NHP and Dean Sullivan from Middy’s Industrial team to ensure seamless integration of cutting-edge technology. The system not only enhances the precision and safety of the trimming process but also showcases our ability to deliver highly customised solutions that meet the evolving demands of our industrial clients.

|

John Pickering

|

What types of work do you and your team specialise in?

At HiTech Electrical Services, we specialise exclusively in industrial electrical work, focusing on heavy industrial and the mining sector. We work with a diverse range of clients, including large corporations and smaller businesses. This variety allows us to handle different types of projects, from installing heavy machinery to routine maintenance of complex electrical systems.

How do you stay ahead of the latest trends, technologies and regulations in the industrial sector?

We stay ahead of industry trends and technological advancements through strong partnerships with our industrial suppliers. They keep us informed about new products and innovations that can benefit our clients. Additionally, our extensive experience in the field prompts us to investigate any new technologies ourselves to assess their viability for our projects. We deal with a wide range of industrial controls, from programmable logic controllers (PLCs) to touch screens and safety systems. This proactive approach allows us to implement the most effective solutions for our customers.

What changes do you see in industrial electrical work in the next 5-10 years, especially with automation and smart technologies?

Technology is evolving rapidly, and I believe that automation will significantly shape the future of industrial electrical work. The ability to control systems remotely using smartphones is just the beginning. In the coming years, I expect to see further advancements in automation and technology that will make processes more efficient and user-friendly. Our team is preparing for these changes by investing in continuous learning and training to ensure we remain at the forefront of the industry's developments.

Is there a specific project or achievement in the industrial space that you are particularly proud of?

One project that stands out for me is our long-standing partnership with Austrak, a company that manufactures concrete rail sleepers. We have worked with them for over 25 years, and a significant achievement was our collaboration during the construction of the railway line from Alice Springs to Darwin. Our team electrically designed and built the machines required for this project and set up factories in multiple locations, including Port Headland, Rockhampton, Katherine and Geelong. It was incredibly rewarding to be part of such a monumental event for Australia, and I take great pride in our contribution to that achievement.

What are the biggest challenges or threats you currently face in the industrial electrical industry?

I wouldn't necessarily describe the changes in our industry as threats, but they do present challenges that we must navigate. For example, the increasing ability to remotely access systems and machinery has transformed the role of on-site personnel. While this allows for greater efficiency in diagnosing and advising on systems, it may reduce the need for as many workers physically present at a site.

Another challenge we face is the impact of the internet on product purchasing. While the online marketplace offers competitive prices, it also leads to customers buying low-quality or incompatible products. These decisions can ultimately lead to more expensive outcomes when systems fail or require additional support. We often need to educate our clients about the long-term implications of their purchasing choices, emphasising that the cheapest option isn't always the most cost-effective in the long run.

|

Andrew Friswell

|

What types of work do you and your team specialise in?

At Friswell Electrical, we primarily focus on industrial work, specifically in the mining and drilling sectors. A large portion of our business involves maintenance and servicing within these projects.

What changes do you see in industrial electrical work in the next 5-10 years, especially with automation and smart technologies?

Automation is already transforming the industry, and I believe it’s going to continue accelerating at a fast pace. In just the next 2-3 years, I expect to see significant advancements, but over the next 5-10 years, the possibilities are staggering. More tasks are becoming autonomous, and it’s exciting to think about how much more can be done as technology progresses. We’re seeing a shift toward systems that are smarter, faster and more efficient, which is going to reshape how we approach electrical work across various industrial sectors.

What’s your vision for the future of industrial electrical work, and how are you or your team preparing for it today?

My vision for the future is all about staying ahead of these technological advancements. We're committed to ensuring that our team is provided with the right training to stay on top of industry advancements. One way we do this is by participating in contractor trips where we get hands-on experience with the latest products and solutions. It’s crucial to be proactive in learning about new technologies so we can continue delivering the best possible service to our clients.

In your experience, which innovations have had the most significant impact on industrial electrical systems?

The biggest game-changer has been automation. It's made tasks not only faster but also more accurate, reducing human error significantly. Whether it's in mining, drilling, or general industrial work, automated systems allow for smoother operations and more precise results. These advancements have made projects more efficient, and the improvements in productivity are hard to ignore.

Is there a specific project or achievement in the industrial space that you are particularly proud of?

Honestly, I take pride in every project we’ve worked on, regardless of its size or scope. Every project comes with its own set of challenges, and whether it’s a large-scale industrial installation or a smaller maintenance job, there’s always a sense of accomplishment when the work is done. Walking away knowing that we’ve done our best always feels rewarding.

What are the biggest challenges or threats you currently face in the industrial electrical industry?

One of the biggest challenges we face today is the shortage of qualified labour, especially in industrial electrical work. It’s becoming difficult to find enough skilled industrial electricians to meet the demand. The industrial sector is growing, and we need more people with the right qualifications and expertise to fill the gaps. This is something we need to address as an industry if we want to keep pace with technological advancements and project needs.